Insight into Working Process of Laser Cleaning Machine

When metal surfaces interact with the air and weather, this is called an oxidation reaction. The metal corrodes because of this reaction, which is also called “rust.” Because of this, parts don’t last as long, and equipment doesn’t work as well. Laser cleaning is a better alternative to traditional methods like blasting, which requires a lot of safety gear for removing rust and stopping corrosion.

Any metal can be cleaned of rust with laser rust removal, which is safe and much faster than other methods. It gets rid of corrosion completely, down to the bare metal, without hurting the metal’s strength. Because of this action, people no longer have to deal with the hassle of getting rid of dangerous trash. Because of this, once the cleaning is done, the job is also done, making this the best way to keep armored cars, planes, and ships in good shape.

It works well, there are no risks, and you don’t have to use harsh chemicals or media to clean with it. When you use laser cleaning, you and your team will save time because it is easy to set up and take down.

How laser rust removal works?

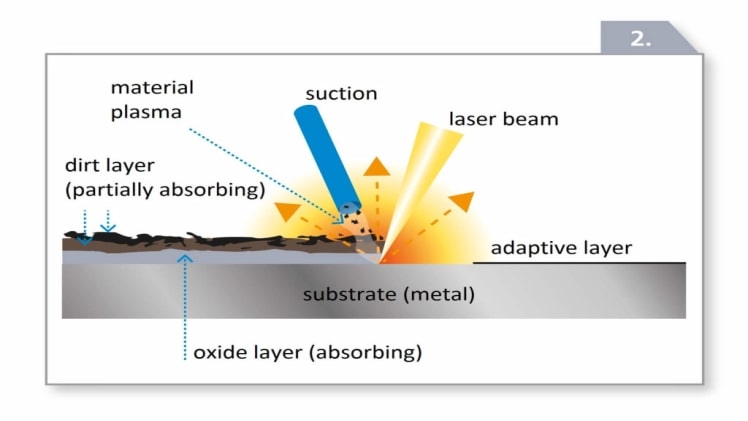

Laser cleaning, which is also called laser ablation, is a process that uses thousands of focused laser light pulses per second to remove pollutants from things like military vehicles, airplanes, and parts used to make cars. In contrast to other ways of cleaning and getting a surface ready for welding, JNCT LASER ablation does not harm the substrate. You will get a thorough cleaning that won’t need to be done again or make more trash. Laser solutions don’t work well on large surfaces, but they work well on smaller, more targeted areas, usually cleaning 15 times faster than options like sandblasting.

Benefits of laser rust removal

Rust is removed without hurting the surfaces underneath or around it.

- Easy to put together and take apart, you can use your hands or a machine.

- Cost-effective

- Not bad for the environment and green

- Specifically tailored to your application’s needs

Laser rust removal, a laser cleaning, is an excellent way to clean metal substrates and parts. Rust and oxide buildup can be taken off with a laser cleaning system. and can be cleaned quickly and thoroughly without damaging the metal underneath.

Laser Cleaning as a treatment before welding

Laser rust removal is the fastest way to improve the quality of any welded piece because it is a very selective process with all of the rust and dirt deposits gone. There are fewer holes in the welding joints, and the scale is two or three times smaller. Because of this, the welds have a higher yield power, tensile strength, flexibility, and fatigue life.

If you weld the parts before painting them, you need to clean off the oxides so that the coating doesn’t disappear over time. Suppose the substrate is shiny before the coating operation; the exact needs to be done. Corrosion is entirely stopped by the laser cleaning process, ensuring that the coated parts are of excellent quality.